The Basics of Power Supply Surge Protection

November 22, 2022 by Ron Stull - 5 Minute Read

The Problem of Power Surges

Voltage surges are a concern of many mains powered devices. Surges can damage power supplies and the devices they power if not properly designed for the intended environment. This article discusses the basics of surge protection by identifying the causes of voltage surges, establishing familiarity with the regulatory surge test standards, and showing surge suppression designs and components.

The three main causes of surges are:

- Lightning

- Load Transients

- Faults

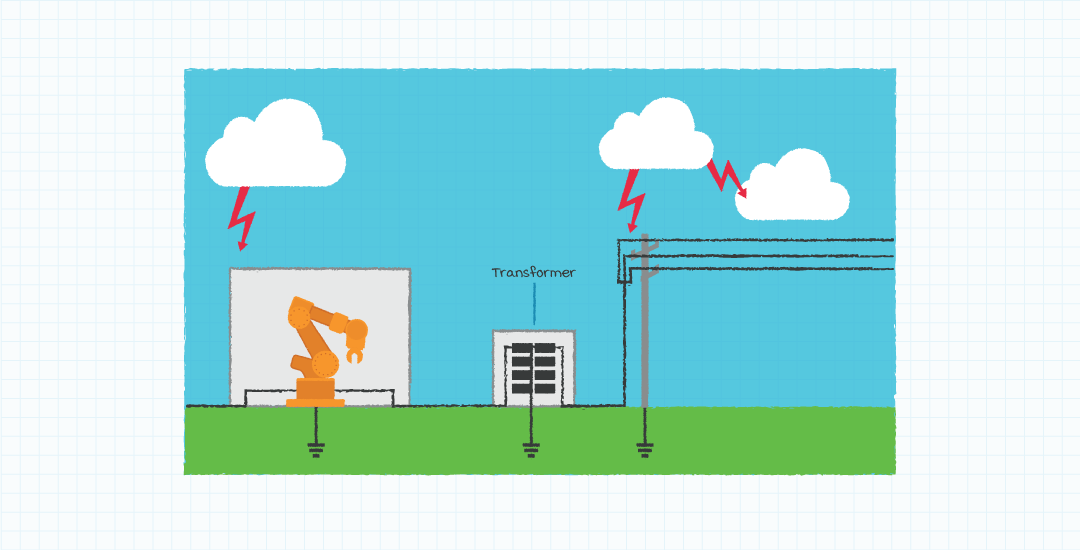

Lightning strikes are a common source of external surge transients and carry far more current at far higher voltages than most electronic systems are rated for. These voltage surges are typically large enough to cause the immediate failure of electronic devices if the appropriate level of protection has not been applied.

Surges on the AC supply line can also be caused when other devices on an electrical circuit are switched on or off. Reactive loads, such as motors or capacitor banks resemble short circuits prior to establishing their electric and magnetic fields. When turning off, the energy stored in these fields can also quickly be dumped back into the system. In both cases, the large and fast current transients can induce voltage spikes and lead to failure of unprotected devices.

Faults can also be the source of surges and lead to excessive voltages being applied to the power supply input. The failure of system components and devices can lead to transient voltages and currents in other parts of the system caused by unintentional shorting or opening of circuits.

The intensity and magnitude of the surge voltage at the power supply input depends on many factors including location, cabling, and the level of surge protection that has been applied to the power supply input, whether internally or externally.

International Standards Define Protection Levels

Standards have been developed to classify and provide guidance on the necessary level of protection. The most common for power supplies is IEC 61000-4-5, from the International Electrotechnical Commission. It is referenced in many national immunity standards, such as EN 55035 which sets immunity requirements for multimedia equipment.

The IEC 61000-4-5 standard defines a standardized test method and different levels of protection based on installation class and coupling methods. Dc power supplies are typically concerned with installation classes 3-5, which have test requirements from 1kV to 4kV (Table 1).

| Installation Class | Dc Power Supplies | Ac Power Supplies | ||

|---|---|---|---|---|

| Line to Line | Line to Gnd | Line to Line | Line to Gnd | |

| 0 | N/A | N/A | N/A | N/A |

| 1 | N/A | N/A | N/A | 0.5 kV |

| 2 | N/A | N/A | 0.5 kV | 1 kV |

| 3 | 1 kV | 2 kV | 1 kV | 2 kV |

| 4 | 2 kV | 4 kV | 2 kV | 4 kV |

| 5 | 2 kV | 4 kV | Depends on power system class | |

Surge Suppression Circuits and Devices

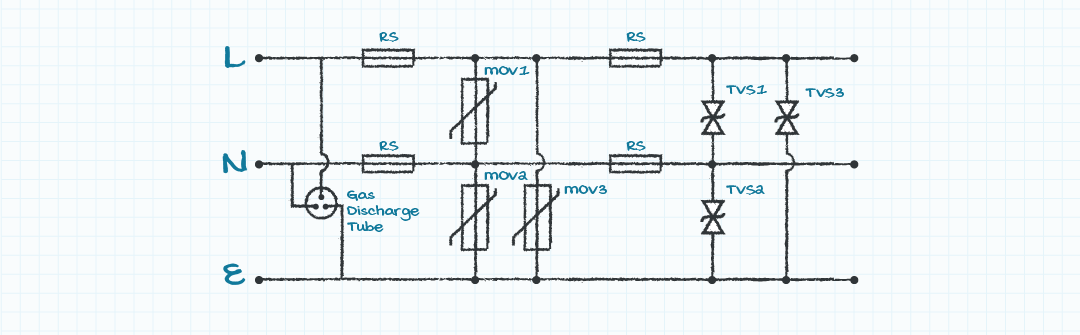

Protecting power supplies and their loads from surges typical requires some form of internal or external surge protection circuit. There are two main classes of surge protection circuits:

- Clamps

- Crowbars

Surge Clamping

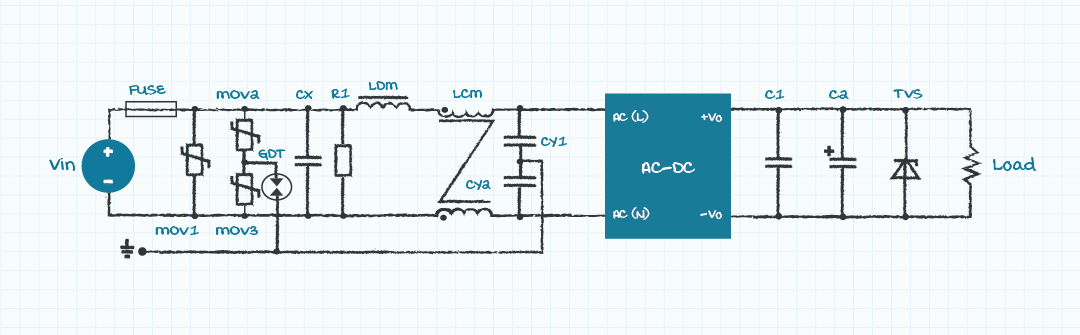

Voltage clamps prevent the voltage from exceeding the chosen clamping voltage. During the surge event the voltage will be held at the clamp voltage and current will be diverted through the clamp until the surge has passed. Two devices commonly used as clamps are transient voltage suppression diodes (TVS) and metal-oxide varistors (MOV). The speed and energy handling capabilities of each is inversely proportional, as seen in table 2. and can lead to the need for combining clamp types.

| Protection Device | Surge Current Rating | Speed |

|---|---|---|

| Transient Voltage Suppression Diodes (TVS) | Low | Fast |

| Metal Oxide Varistors (MOV) | Medium | Medium |

| Gas Discharge Tubes (GDT) | High | Slow |

Transient Suppression Diodes

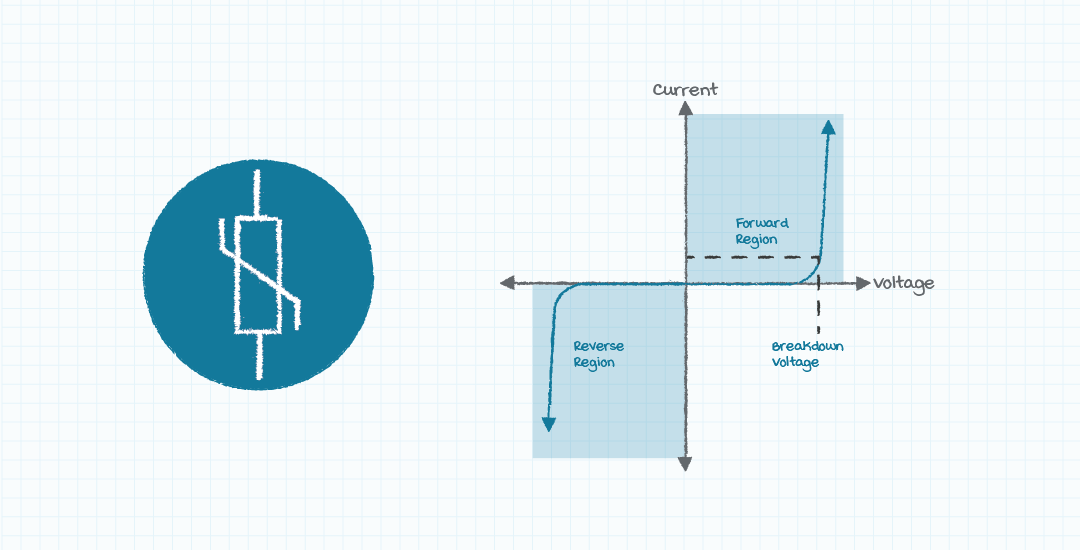

TVS’s are diodes that are designed to absorb the excess energy of a voltage spike and thus clamp it. They can be either unidirectional or bi direction. These diodes have a knee voltage like a Zener diode above which the diode will begin conducting. This causes the voltage to be clamped at the knee voltage and the excess energy to be diverted away from the power supply.

Varistor Clamps

The bidirectional semiconductor metal oxide varistor (MOV) is a voltage-sensitive variable resistor. MOV’s have a high resistance at low voltage and low resistance at high voltage. It provides a softer clamp voltage and has slower reaction time than TVS diodes. MOV’s also wear out and can handle only a limited number of surge events. However, due to their low cost and surge handling capabilities, they are commonly used for surge protection in power supplies.

Crow Bar Circuits

The crowbar is a different type of surge protection circuit. Crowbar devices, rather than limit the voltage to a maximum value, short the circuit nodes together, bringing the voltage close to zero. Gas discharge tubes (GDT) are commonly used as a crowbars. GDT’s, similar to TVS’s, act as a voltage dependent switch. This device behaves as an open circuit normally and a short circuit when its voltage threshold is exceeded. GDT’s can handle more current but also tend to be the slowest reacting surge protection device. Power supplies sometimes use them in conjunction with other methods for a more robust solution.

Surge Immunity in Off-the-Shelf Power Supplies

Off-the-shelf power supplies may or may not have internal surge protection. Board mount power supplies offer a range of options from no internal protection to the maximum level of protection. Often, manufacturers provide reference designs to improve the inherent performance level. The designer needs to pay attention to the datasheet to see if the manufacturer’s external circuit meets the appropriate performance level for the application.

Surge Prediction and System Evaluation

The nature of voltage surges is that any individual surge is completely unpredictable. That said, it is still possible to evaluate a system and anticipate what types of surges it might be subject to and recommend an appropriate amount of surge protection. The appropriate level could vary. Some systems can be expected to experience mostly common and relatively easy to handle over voltages. For example, other nearby equipment switching on and off. The other extreme might be a system in an area where there is a great deal of lightning activity. In that case, protection to handle spikes of greater severity would probably be recommended. There are plenty of different circumstances between those two extremes, and that’s what experts like CUI can help select the right power supply for your application.

Fundamentals , Product Selection , Safety & Compliance

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com