Understanding IEC Overvoltage Categories

April 27, 2021 by Ron Stull - 5 Minute Read

Ensuring equipment connected to high-voltage power supplies has a suitable overvoltage-withstand capability, in accordance with IEC specifications, is vital to meet industry safety requirements.

Overvoltage and Safety

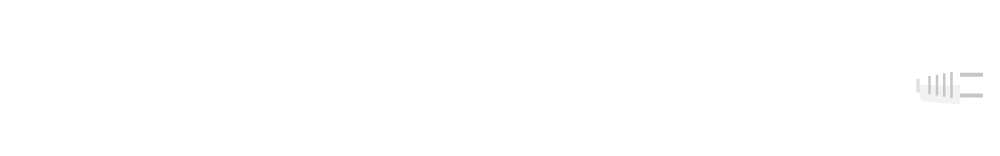

Overvoltage transients on power lines can damage equipment connected to them, causing failures that are not only inconvenient and expensive but may also expose users to danger. To design electrical equipment that is capable of withstanding likely transients, to ensure reliability and safety, engineers should be familiar with the overvoltage categories (also known as installation categories) defined by the IEC.

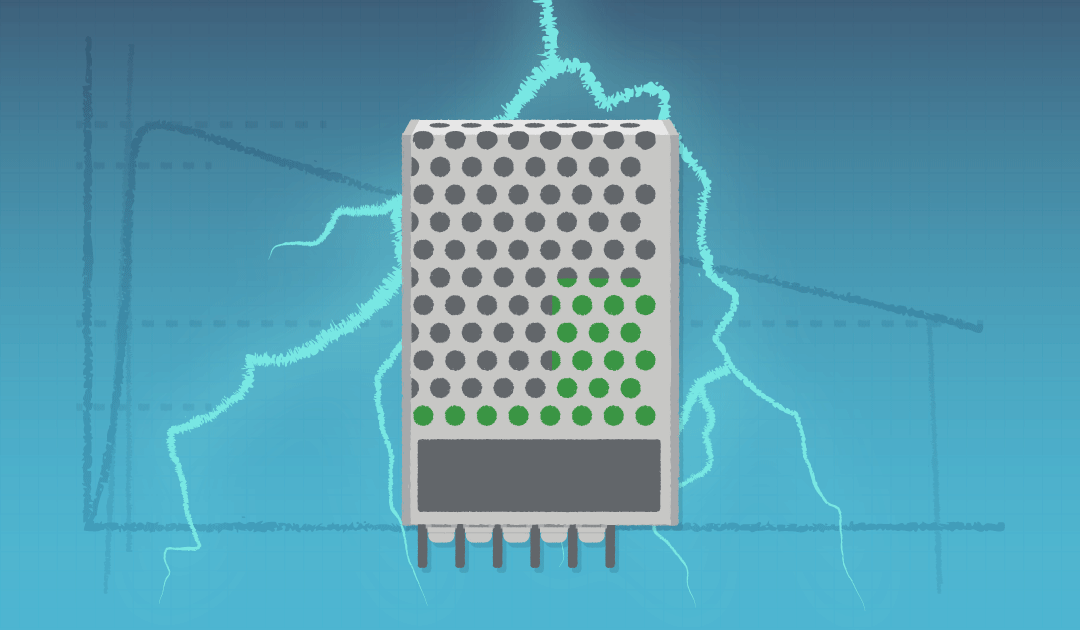

Four overvoltage categories are defined:

- Category I is the lowest overvoltage category and applies to circuits that contain measures to limit overvoltage transients to a low level.

- Category II describes transients that could be applied to equipment supplied from a fixed installation. In a domestic context, for example, appliances designed to be plugged into wall outlets in the house, such as power tools, televisions, or similar must be able to withstand category II overvoltage.

- Category III applies to equipment inside the fixed installation, such as switches in a domestic fuse panel, or equipment permanently connected to the fixed installation such as air conditioners or industrial machinery hard-wired to the ac supply.

- Category IV is the highest overvoltage category and applies to equipment used at the origin of the installation; that is, connected directly at the utility side. Examples are distribution panels, utility-grade transformers, and meters.

The diagram below helps to place these categories in context.

In category IV, large voltage transients are expected. Transients seen by category III equipment, on the other hand, are diminished due to wiring impedance and the effects of fuses and circuit breakers present in the system.

In the case of category II, which applies to the consumer side of the fixed installation, transient voltages are lower than in category III due to the additional impedance of wiring circuits. Wall-plug outlets are usually regarded as category II sources, thanks to the transient suppression properties of the power distribution infrastructure within the building. The category II limits also apply to equipment such as light switches positioned more than 10 meters from a category III source.

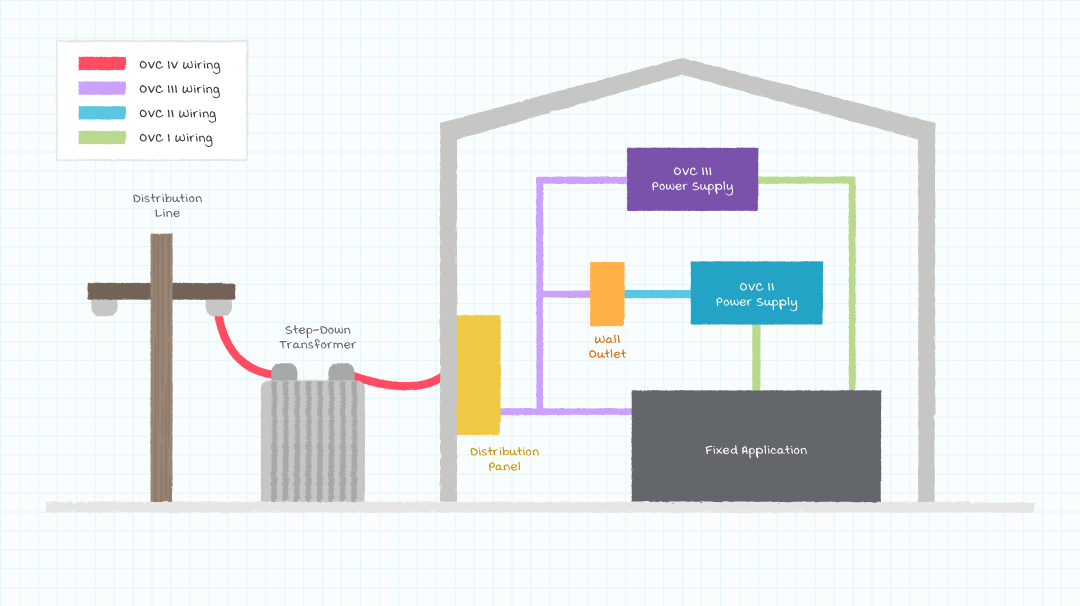

Table 1 summarizes the overvoltage requirements that apply to equipment in the various categories according to the working voltage, or nominal voltage. Note that interpolating the nominal voltage is not allowed. Hence, equipment to be operated at 250 V in a category II application must be designed for overvoltage transients up to 2500 V.

| Transient Voltage Tolerated | |||

|---|---|---|---|

| Nominal Voltage (Vac) | Category I | Category II | Category III |

| 50 | 330 | 500 | 800 |

| 100 | 500 | 800 | 1500 |

| 150 | 800 | 1500 | 2500 |

| 300 | 1500 | 2500 | 4000 |

| 600 | 2500 | 4000 | 6000 |

| 1000 | 4000 | 6000 | 8000 |

These overvoltage categories are referenced in various equipment safety standards, including (but not limited to) IEC 60664-1, which describes insulation requirements for equipment with rated voltage up to 1000 Vac; IEC 60209-1, the safety standard for solar power converters; IEC 60204-1 covering the safety of machinery; and IEC 61010-1 that covers electrical equipment for purposes such as test and measurement, process control, and laboratory equipment.

Design to Meet Safety Standards

The key aspects of equipment design that influence the overvoltage capability include the voltage rating of protective insulation, the isolation provided by electrical components like transformers and optical isolators, creepage and clearance distances, and the cross-sections of cables and interconnects. Designers must pay attention to these to achieve the required capability, as a part of ensuring overall compliance with the applicable safety standard.

If the equipment is to be designed using an off-the-shelf power supply, it is important to check the overvoltage category when choosing an appropriate PSU. Only a category III power supply can be connected directly to a category III source. However, equipment designed with a category II power supply can be powered from a category III source if a suitable isolation transformer is connected between the source and the power supply input.

A category II power supply can be connected directly to a category II source, such as a wall outlet. You can connect a category III power supply if high reliability or availability of the connected equipment is critical. On the other hand, additional protection is needed to connect category I equipment to a wall outlet. This may be an isolation transformer, as before, or a power supply designed to suppress the category II transients.

Power Supply Selection

CUI has a range of standard power supplies for category II and category III applications. Standard internal ac-dc power supplies such as the VGS-100W series are designed for category II applications. Series such as the VGS-100D are designed with higher input-overvoltage capability for use in category III fixed installations. Both series incorporate robust design features, with output over-voltage, short-circuit, and over-current protection built-in, a wide input-voltage range up to 305 Vac, and IEC/EN/UL 62368 general safety certification. The units also comply with IEC/EN 61558 for power supplies and transformers, and IEC/EN 60335 for household appliances.

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com