Unleashing Efficiency: Powering 1500V Photovoltaic Systems

October 12, 2023 by Ron Stull - 5 Minute Read

The Global Solar Market

The solar power landscape is in a constant state of evolution, pushing the boundaries of efficiency and financial viability. One significant trend shaping the future of photovoltaic (PV) systems is the transition to larger strings of cells, delivering higher DC voltages for conversion to AC power. While this move results in cost savings, engineers must address the challenge of adapting auxiliary power supplies for monitoring and control to accommodate these higher voltages.

Despite fluctuations in government support, the growth of PV power generation systems remains robust. From 178 GW in 2014, global installed capacity is projected to reach a staggering 540 GW by 2019. Europe leads this charge, expecting a boost to 158 GW, but other nations, such as China and the United States, anticipate remarkable growth as well.

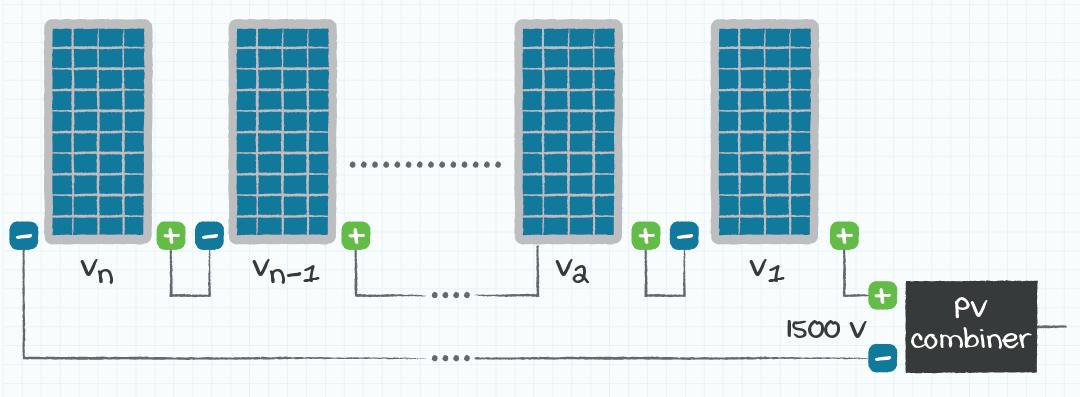

The Move to 1500 V PV Systems

Efficiency has always been a critical factor in justifying the cost of PV systems. Currently, designers are maximizing efficiency by connecting panels in series, resulting in higher DC voltages. For instance, a typical grid-connected system might have 22 panels in series to produce 1000 V. However, a shift to 1500 V can lead to a substantial decrease in current and resistive cable losses, resulting in higher overall system efficiency or a lower installation cost.

The potential deployment savings in large scale solar plants when transitioning from 1000 V to 1500 V are significant. This results from reductions in the overall component count and decreased unit costs of PV modules, combiner boxes, PV inverters, and more.

It's crucial to note that while the advantages of higher string voltages are evident, there are potential downsides. Insulation throughout the system must be upgraded to handle the higher operating voltage. However, advancements in inverter technology, particularly the use of wide bandgap semiconductor devices, are facilitating this transition to 1500 V.

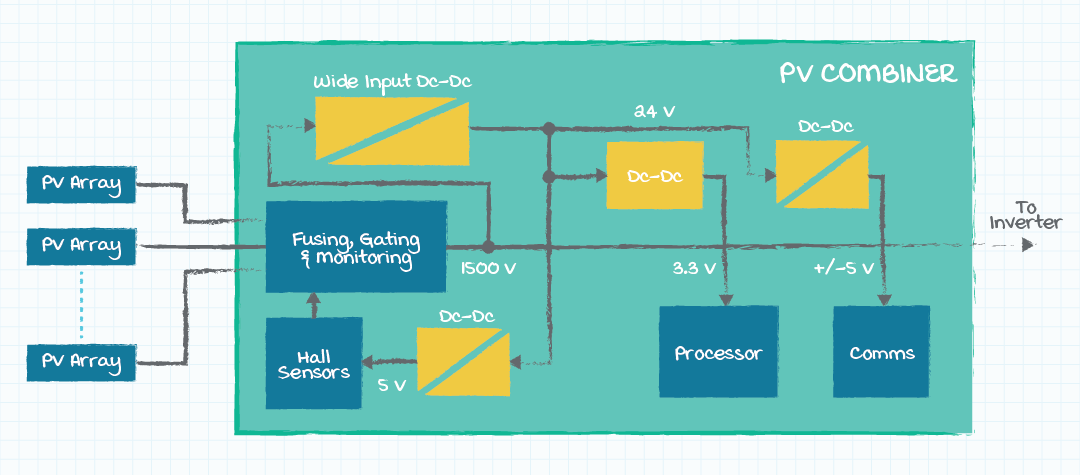

Auxiliary Circuit Challenges

One area demanding attention in this transition is the adaptation of auxiliary power supplies for monitoring and control. PV combiners and inverters require low voltage isolated power derived from the 1500 V line. The challenge lies in the scarcity of small DC-DC converters operating at these levels. Additionally, these converters must handle a wide input range, as the output from the solar cells can fluctuate significantly, dipping as low 200V.

Complying with safety standards, such as IEC 62109-1, is also essential for a DC-DC converter in this application. This standard ensures protection against hazards like electrical shock, mechanical, temperature, fire, and chemical risks. Selecting a DC-DC converter that has been designed specifically to meet these requirements can speed up the applications certification process and reduce time to market.

In the US, another relevant standard is UL 1741, covering the more general application of 'Distributed Energy Resources.' It includes specific requirements for converters and controllers.

Meeting Design Challenges Head-On

To address the design challenges associated with auxiliary power supplies, companies like CUI are introducing off-the-shelf solutions. For instance, CUI's AE series of DC-DC converters are specifically designed for 1500 VDC photovoltaic systems. These converters offer a wide input range, varying power ratings, and output voltages, all while meeting the stringent IEC 62109-1 safety requirements for power conversion equipment in PV systems.

Transitioning to 1500 VDC Systems

As PV systems aim for efficient energy conversion on a gigawatt scale, the role of comprehensive control and monitoring becomes paramount. Auxiliary power supplies play a crucial role in ensuring the smooth functioning of the system. CUI's offerings provide a 'fit-and-forget' package for PV system designers and integrators, addressing the specific challenges associated with high operating voltages while adhering to reliability and safety standards.

The transition to 1500 VDC in solar systems presents a compelling case for increased efficiency and cost savings. However, engineers must navigate challenges in adapting auxiliary power supplies to accommodate these higher voltages. With off-the-shelf solutions like CUI's AE series, the industry is poised to embrace the future of solar power with confidence, moving towards a more sustainable and economically viable energy landscape.

Industry News , Product Selection

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com