Insulation, Isolation, and Working Voltage

February 18, 2020 by Bruce Rose - 6 Minute Read

Power supplies allow electrical systems to operate by providing a required voltage or current at a proper power level. In addition to energizing an electrical system, power supplies must be designed in a manner which minimizes the risk of injury to the end user. In this post, we address the question, “How do the concepts of insulation types, isolation voltages, and working voltage apply when addressing safety concerns for power supplies?"

- Insulation type describes how electrical insulation is utilized in a power supply

- Isolation voltage relates to the maximum voltage at which the power supply will prevent dangerous voltages for short time durations

- Working voltage describes the recommended operating conditions for the power supply over an extended period of time

Insulation Types

In the world of electronics, insulators are defined as materials which do not permit the flow of electric current. Standards exist which define the purposes for five different types of insulation:

- Functional

- Basic

- Supplementary

- Double

- Re-enforced

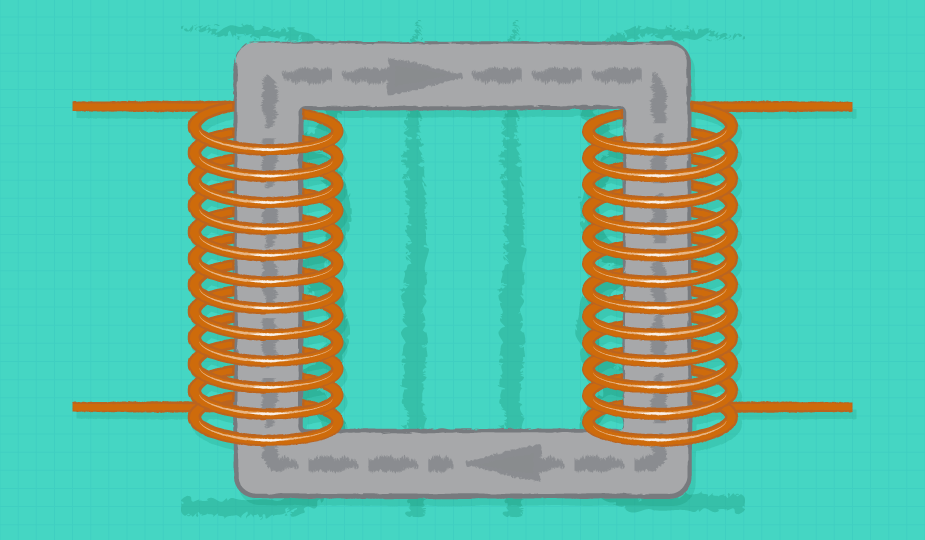

Functional Insulation

Functional insulation may also be referred to as operational insulation. The purpose of this insulation is to ensure the correct function or operation of a product and is not used to isolate the user from dangerous voltages. One common example is the enamel insulation around wire used to wind a coil. The insulation only needs to be strong enough to prevent the adjacent windings of the coil from shorting together. Another example would be the insulation between the traces of a low voltage powered PCB. The insulation of these PCB traces serves to ensure the traces do not short to each other so that the circuit functions properly and not for safety concerns. Safety regulations do not address the performance of functional insulation.

Basic Insulation

Basic insulation is a single layer of insulation that provides protection from hazardous voltages. An example of basic insulation is the plastic insulation around each conductor of a common ac power cord. A layer of basic insulation is sufficient to protect the user from electrical shock, but if for some reason there is a failure of the basic insulation then the user could be exposed to hazardous voltages.

Supplementary Insulation

Supplementary insulation is a second layer of insulation that is independent of the basic insulation. The purpose of this layer of insulation is to provide protection from hazardous voltages if there is a failure of the basic insulation. Supplementary insulation is included in addition to basic insulation when safety ground is not present in a power supply. An example of supplementary insulation is the plastic case of an external power supply.

Double Insulation

Double insulation is the inclusion of both basic and supplemental insulation in a design and can be viewed as a level of safety rather than as a type of insulation (most documents will list double insulation as a type of insulation). Both the basic and supplemental insulation layers are implemented due to the concern that the layer of basic insulation may be compromised and then the user would be exposed to hazardous voltages.

Re-enforced Insulation

Re-enforced insulation achieves the same level of safety as would be present with double insulation, but it is implemented with a single layer of insulation. The requirements for an insulation to be classified as re-enforced are more stringent than those for basic or supplementary insulation.

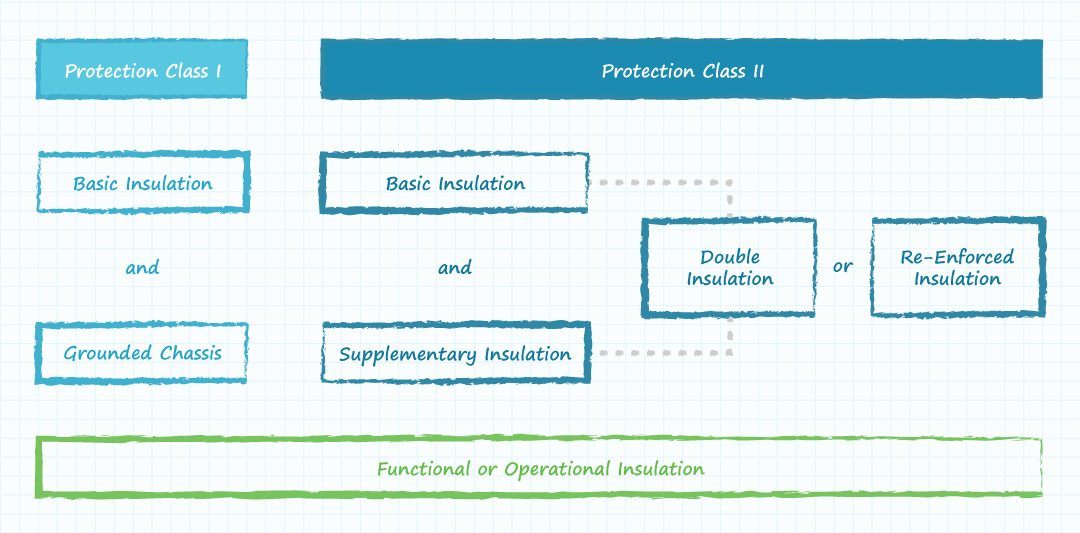

Product Protection Classes

Regulatory standards have created protection classes of products that are characterized by the means of providing operator protection from hazardous voltages. In a Class I product there will be a conductive chassis which is connected to safety earth ground. Thus, an input power cord with a safety earth ground conductor is required in protection Class I products. A protection Class II product will not have a safety earth ground conductor in the input power cord and thus a second layer of insulation is included for operator protection due to the absence of the grounded chassis.

Isolation Voltage

Isolation voltage refers to a test of the ability of an insulator to minimize the flow of electric current with a high applied voltage. Most insulators exhibit extremely high impedance (extremely low current flow) until the applied voltage (and thus the resultant voltage field strength) is great enough to ‘break down’ the insulation. Once the insulation breaks down, it stops behaving as a good insulator and then serves as a poor conductor. Dangerous levels of current can flow across an isolation barrier after the insulation has broken down.

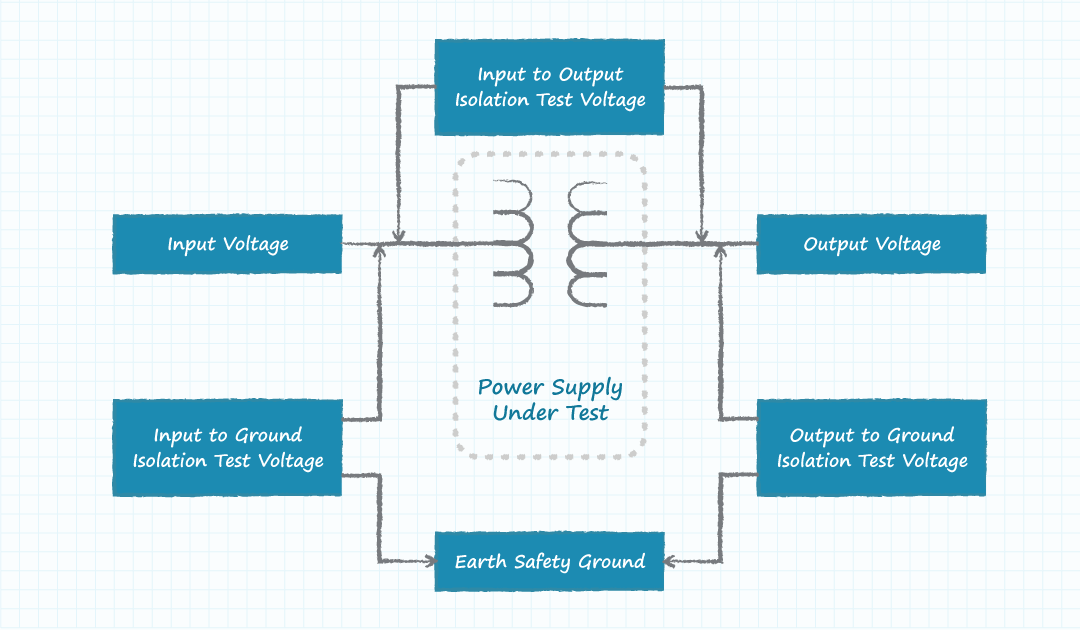

The breaking down of insulation is dependent upon both the magnitude and the duration of the applied voltage stress. For this reason, the specifications of isolation voltage include a voltage magnitude of the test voltage, a time duration of the test voltage and a maximum allowed current flow during the test voltage stress. The voltage waveform used for isolation voltage testing can either be a sinusoidal ac voltage or a dc voltage. The well-understood ratio of the square root of two between the RMS and peak value of a sinusoidal waveform allows the test voltage to be specified as either an ac or a dc voltage. Common safety related isolation voltages specified for power supplies include input to ground, input to output, and output to ground.

Working Voltage

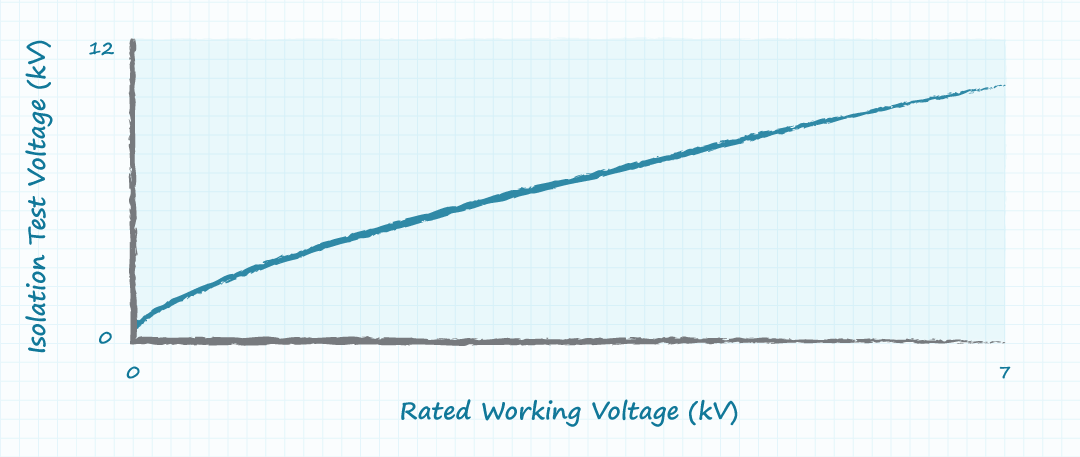

While the concept of isolation voltage is to apply a high voltage for a short duration and observe the behavior of the insulation, the concept of working voltage applies to the behavior of the insulation at a voltage level that may be present for an extended period. The voltage stresses applicable to working voltage may come from the normally applied ac or dc input voltage, the voltage offset between the input and the output voltages, or between either of those voltages and safety earth ground. At the voltage field strength present from the working voltage, the quality of the insulation remains and does not degrade over time. At lower tested isolation voltages, the recommended working voltage may be only one tenth of the tested isolation voltage. At higher tested isolation voltages, the working voltage may be greater than half of the tested isolation voltage.

Conclusion

Different types of insulation are used to perform different functions in electronic products. Sometimes the purpose of insulation is to allow a circuit to function properly, while another purpose of insulation can be to protect the user from hazardous voltages. Insulation will fail or break down if a high enough voltage is applied for a long enough period. The result from testing for failure of the insulation is labeled as the isolation voltage of the insulation. The recommended working voltage of insulation is derived from the results of the isolation voltage testing. The working voltage is a recommended level at which the insulation incorporated in the product will protect the user from dangers of electric shock.

Fundamentals , Safety & Compliance

You May Also Like

Have comments regarding this post or topics that you would like to see us cover in the future?

Send us an email at powerblog@cui.com