What is the arcTEC Structure?

CUI Devices’ innovative arcTEC™ structure combats the effects of thermal fatigue found in thermoelectric modules by incorporating a thermally conductive resin between the electrical interconnect and ceramic on the cold side of the module, high temperature solder, and larger P/N elements made from premium silicon ingot. The combination of these three enhancements greatly improves the reliability, performance, and cycle life of Peltier modules built with the arcTEC structure, allowing them to outperform conventional thermoelectric coolers in the most demanding applications.

Key Technology Features and Benefits:

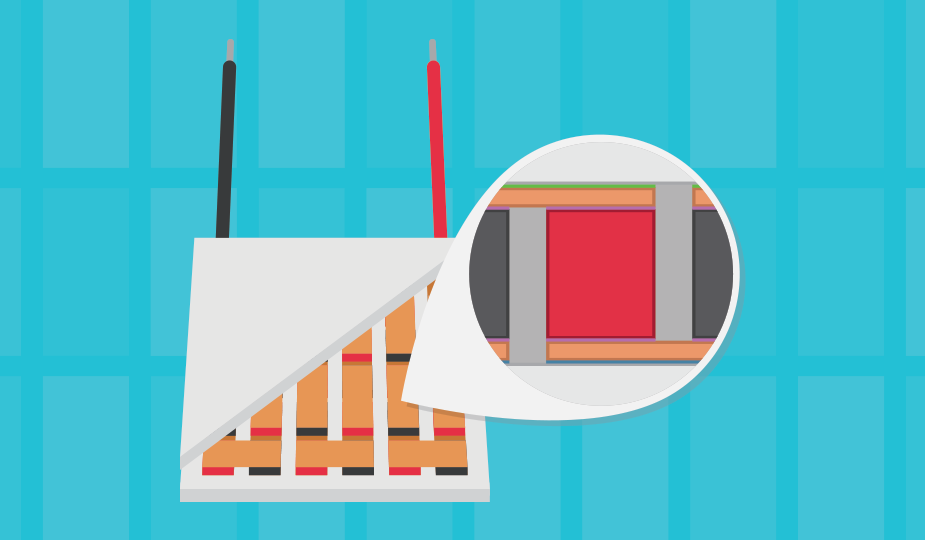

Thermal Resin

Thermally conductive resin allows for repeated thermal expansion and contraction, resulting in: better thermal connection, superior mechanical bond, and no marked drop-off in performance over time.

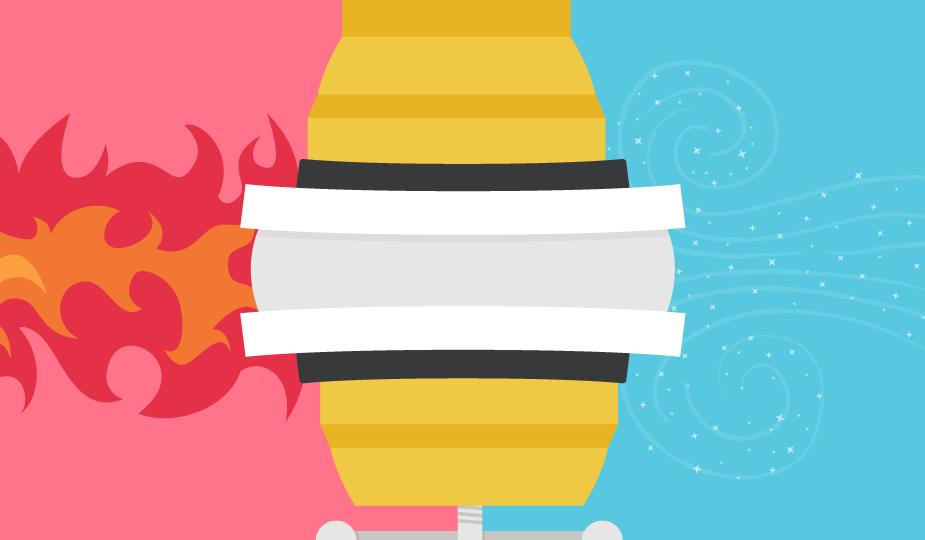

Improved Solder

High temperature SbSn solder carries a 235°C melting point, offering superior resistance to thermal fatigue and better shear strength when compared to the 138°C melting point of typical BiSn solder.

Larger Semiconductors

Larger P/N elements made from premium silicon ingot are as much as 2.7 times larger than other P/N elements on the market, leading to faster, more uniform cooling.